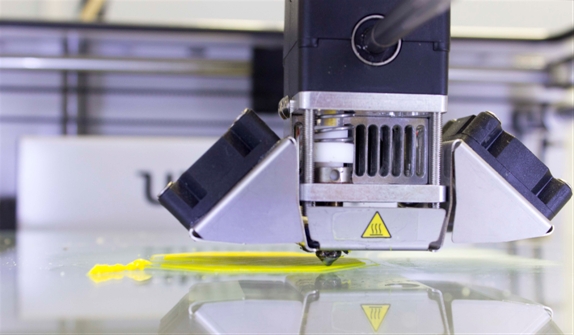

Just press print – and prototypes like a cellphone cover, decorative crockery and cutlery handles are seemingly magically produced in the CCDI’s popular 3D printing workshops.

Jewellers, industrial designers and illustrators are among those who are discovering how 3D printed objects can boost their prototyping and manufacturing processes.

The technology of 3D printing, also called additive or rapid manufacturing, is based on creating an object by stacking one layer of material (such as plastic) on top of another. This means that there is a physical object to work with very early in the design process.

“You can make a piece of jewellery, for example, by casting it from a mould made by a 3D printer, and then work on personalising each piece,” explains CCDI Product Support facilitator David van Staden. “You then spend more time on modifications, redesigns and testing. So if you can improve your design early, you can get to the market sooner… with a much better design.”

The four-day workshops take place in the CCDI’s Product Support Space, which is an extremely well-resourced facility where trained facilitators take users throughout the process of exploring an idea for a product or design (or refining existing products).

On the 3D printer workshops, participants learn how to use 3D modelling software and 3D printers, as well as mould-making and casting. Day one involves a discussion of and introduction to 3D modelling software using 123Design. Day two covers scanning and generating your own models, progressing to co-creating a product with fellow participants on the third day. Day four covers 3D printing and manufacturing without tooling or assembly lines. Innovation and experimentation are encouraged by developing component parts to print and test.

“The participants have varied professions and backgrounds, but the common thread is they are curious about 3D printing and want to find out how it can be applied to their enterprises and projects,” said David.

Some of the positive feedback includes: Caryn Kohler, a graphic designer from The Design Lounge, said: “I really enjoyed this course and learned a lot. I think the CCDI is very well run and organised and all the courses on offer benefit small businesses, helping us keep up with new technology.”

Siphiwe Giba, a creative director from Juxtapoz Concepts, admired “the professionalism, state-of-the-art lab and equipment” and said “the staff here are very helpful and I really appreciate their time and energy.” Elizabeth Forson, a jewellery design student from Philip Joubert Juweliers, added: “I learned about alternative methods of design and production of handles for cutlery and got a general understanding of 3D printing. Great facilities.”

In addition to the 3D printers, the Product Support Space offers access to a wide spectrum of tools and processes. In one location, there is everything from basic hand tools and workshop machinery (such as a sander and a band saw), to sophisticated, computerised equipment.

The Space operates on the principle of “assisted DIY” using a one-on-one consultation system, allowing the skilled advisors to give hands-on, personal attention. They will guide visitors through the entire problem-solving process, from exploring ideas through research and conceptualisation, to helping make prototypes. The advisors are also experienced in product refinement, making production aids, creative branding and packaging.

WHEN: Product Support Workshop 3D Printing 14-17 July 2015